Environmental evaluation of a Geothermal Power Plant in the Southern German Molasse Basin by a Life Cycle Analysis

On the 26th March 2021, ENERCHANGE and ThinkGeoEnergy hosted a new episode of their recurring Focus on Geothermal – Energy for the Weekend event this time focused on Life Cycle Assessment of Geothermal Energy to raise public acceptance based on a German Case Study.

Geothermal Energy and social acceptance

The webinar highlighted the competitive disadvantage of geothermal energy compared to other energy sources due to public opinion. Despite of its green potential and output advantages (baseload capacity, long lifetime of operation and wide accessibility), geothermal is often perceived a harmful energy source by general public.

According to the present case study and similar past conclusion of experts, the roots of poor social acceptance performances of geothermal energy lie in poor communication of geothermal green capacities compared to other energy sources both fossil and green. The German team hosting the event suggested that a clear demonstration of the green output of geothermal energy could outweigh negative initial views on the technology. In addition, the team believes that a strict environmental monitoring of geothermal power plants is necessary to showcase transparency, accountability and good faith of geothermal developers. To that end, the team proposed that geothermal projects shall establish a thorough Life Cycle Assessment (LCA) of their operations from exploration to decommission to monitor CO2 emissions and take measures if levels are abnormally high.

Life Cycle Assessment for geothermal projects

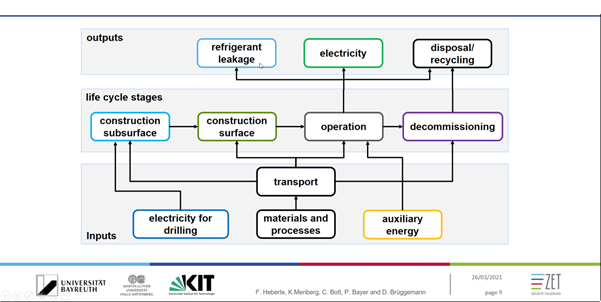

A Life cycle assessment is a technique to assess environmental impacts associated with all the stages of a product’s life, spanning from raw material extraction through materials processing, manufacture, distribution, and use.

Possible considerations of a Life Cycle Assessment for Geothermal plants.

Based on this new operational framework for a Life Cycle Assessment in geothermal, 3 steps have to be taken into account when assessing geothermal power plants:

- Drilling geothermal wells require energy (often electricity) whose origin (fossil v. renewable) has to be taken into account. Furthermore, building a plant requires, raw materials, transport and auxiliary energy. All of which have a carbon footprint. The total energy demand for input will be accounted for in the calculation of the environmental impact of a project.

- The same principle applies for the output of a station. Whilst the electricity produced by a geothermal power plant might be 100% clean, it bears the limitations of transport of raw materials for construction and the building of the plant itself.

- Finally, it is necessary to ensure that refrigerant used in geothermal turbines shall not leak which would have a detrimental impact on the environment. One way to ensure transparency and maintenance of high safety standards throughout the lifetime of a geothermal plant is to enforce environmental monitoring. Said monitoring shall be available to the public to showcase the good performance of geothermal energy which would then improve social acceptance of the technology once the public sees for itself that geothermal has great versatility coupled with high environmental standards.